Carbon steel is a type of steel that contains carbon as the primary alloying element. The amount of carbon in carbon steel typically ranges from 0.05% to 2.0%. The material of carbon steel can vary depending on the specific grade and composition, but it typically includes the following elements:

- Iron (Fe): The main component of steel, which makes up the majority of the material.

- Carbon (C): The primary alloying element in carbon steel, which gives it its strength and hardness.

- Manganese (Mn): Added to improve strength, toughness, and hardenability.

- Silicon (Si): Added to improve strength and reduce surface defects.

- Sulfur (S): Typically present in small amounts to improve machinability.

- Phosphorus (P): Added to improve strength and corrosion resistance.

Other elements that may be present in carbon steel include nickel (Ni), chromium (Cr), and molybdenum (Mo), which are added to improve corrosion resistance and other properties depending on the specific application.

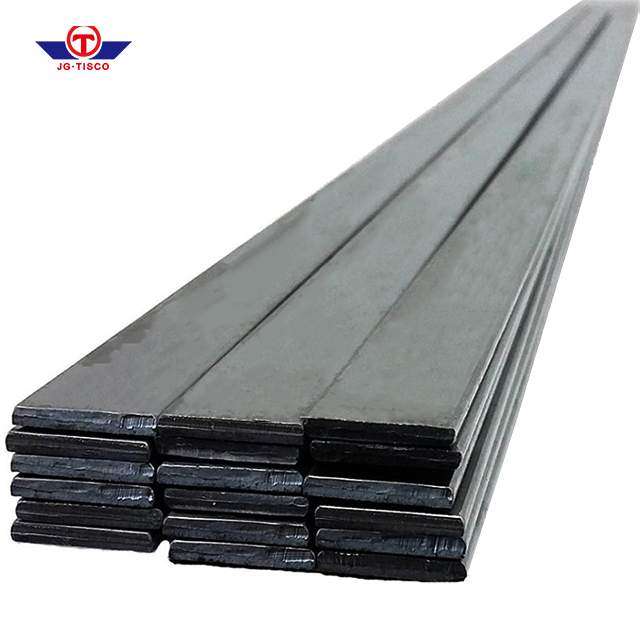

Carbon steel is a type of steel that contains carbon as the main alloying element, with a maximum carbon content of up to 2.1%. Carbon steel is one of the most widely used materials in various industries such as construction, automotive, and manufacturing, among others.

The presence of carbon in the steel improves its strength, hardness, and durability. However, higher carbon content also makes the steel more brittle and less ductile, so the amount of carbon is carefully balanced to achieve the desired properties.

Carbon steel is further classified into several categories based on the carbon content and other alloying elements. For example, low carbon steel has a carbon content of up to 0.3%, while high carbon steel has a carbon content of up to 2.1%. Carbon steel can also be alloyed with other metals, such as manganese, to improve its properties.

Carbon steel is a widely used material due to its strength and durability. It is a type of steel that contains carbon as the primary alloying element, typically ranging from 0.12% to 2%. Carbon steel is often used in a variety of industrial applications, including:

Construction: Carbon steel is frequently used in the construction of buildings, bridges, and other structures. Its high strength-to-weight ratio and durability make it a popular choice for structural components such as beams and columns.

Transportation: Carbon steel is commonly used in the automotive and aerospace industries to make components such as engine parts, gears, and landing gear.

Manufacturing: Carbon steel is used to make a wide range of industrial equipment and machinery, including piping, valves, and tanks.

Energy: Carbon steel is frequently used in the oil and gas industry to make pipelines and other equipment due to its high strength and resistance to corrosion.

Tools: Carbon steel is also used to make cutting tools such as knives and saw blades due to its hardness and ability to hold a sharp edge.

Overall, carbon steel is a versatile and widely used material in a variety of industries due to its strength, durability, and versatility.

Choosing carbon steel depends on several factors, including the specific application, desired properties, and budget. Here are some general tips:

Determine the application: Carbon steel is commonly used in a variety of industries, including construction, automotive, aerospace, and manufacturing. Determine the specific application for which you need carbon steel to ensure you choose the right type and grade.

Consider the properties: Carbon steel comes in different grades, each with different properties. Some grades are more ductile and malleable, while others are stronger and more durable. Consider the desired properties of the steel, such as strength, hardness, toughness, and corrosion resistance, to choose the appropriate grade.

Check the carbon content: Carbon steel is classified based on its carbon content. Higher carbon content usually means higher strength and hardness but lower ductility and toughness. Lower carbon content usually means lower strength and hardness but higher ductility and toughness. Consider the appropriate carbon content for your application.

Evaluate the production process: Carbon steel can be produced using various methods, such as hot-rolling, cold-rolling, or forging. Each production process can affect the properties of the steel. Consider the production process used to ensure you get the desired properties.

Consider the budget: Carbon steel comes in a wide range of prices, depending on the grade, quality, and production process. Consider your budget and choose the best quality steel within your price range.

Overall, choosing carbon steel involves careful consideration of the application, desired properties, production process, and budget. It may also be helpful to consult with a steel supplier or engineer for advice on the best type of carbon steel for your specific needs.

Shandong Jiugang Tisco Steel Co., Ltd. is located in the beautiful spring city -Jinan ,the capital of Shandong province. Our company registered capital beyond RMB 50 million. We are a comprehensive group company integrating R&D, production, sales and service of steel products.

If you are interested in stainless steel or carbon steel,please contact us. Tel: +86-13375310907 E-mail: Jgtisco@gmail.com

Shandong Jiugang Tisco Steel Co., Ltd.

Shandong Jiugang Tisco Steel Co., Ltd.