1060 Aluminum sheet Chemical Composition

and Mechanical Properties

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | – | 0.05 | 0.03 | 0.15 | Remain |

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation | ||||||

| Thickness(in.) | (ksi) | (ksi) | (%) | |||||||

| 1060-O(annealed) | 0.006-0.019 | 8.0-14.0 | 2.5 | Min15 | ||||||

| 0.020-0.050 | Min22 | |||||||||

| 0.051-3.000 | Min25 | |||||||||

| 1060-H12/1060-H22 | 0.017-0.050 | 11.0-16.0 | 9.0 | Min6 | ||||||

| 0.051-2.000 | Min12 | |||||||||

| 1060-H14/1060-H24 | 0.006-0.019 | 12.0-17.0 | 10.0 | Min1 | ||||||

| 0.020-0.050 | Min5 | |||||||||

| 0.051-1.000 | Min10 | |||||||||

| 1060-H16/1060-H26 | 0.006-0.019 | 14.0-19.0 | 11.0 | Min1 | ||||||

| 0.020-0.050 | Min4 | |||||||||

| 0.051-0.162 | Min5 | |||||||||

| 1060-H18/1060-H28 | 0.006-0.019 | Min16.0 | Min12.0 | Min1 | ||||||

| 0.020-0.050 | Min3 | |||||||||

| 0.051-0.128 | Min4 | |||||||||

| 1060-H112 | 0.250-0.499 | Min11.0 | Min7.0 | Min10 | ||||||

| 0.500-1.000 | Min10.0 | Min5.0 | Min20 | |||||||

| 1.001-3.000 | Min9.0 | Min4.0 | Min25 |

1060 aluminum sheet has the characteristics of excellent electrical conductivity, thermal conductivity, plasticity, and extensibility of pure aluminum, but its own strength is low, it cannot be strengthened by heat treatment, and machinability is not good.Electrical conductivity 55% of copper.

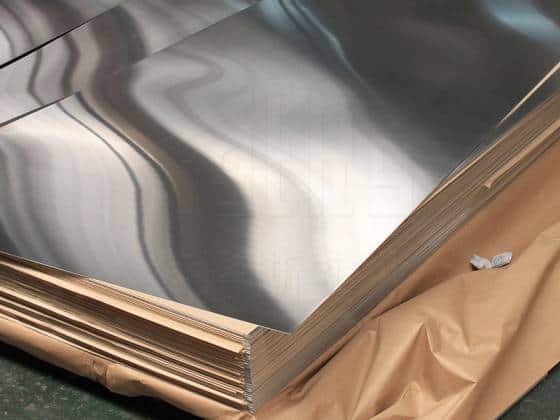

aluminum sheet interleaved with paper

The same as 1050 aluminum sheet, the aluminum sheet 1060 is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave containers, welding parts, heat exchangers, clock surfaces and disk surfaces, nameplates, kitchenware, decorations, reflectors and so on.

Because the production process of 1060 aluminum sheet is relatively single, the technology is relatively mature, and the market price is very advantageous.

1060 alloy aluminum may be forged in the temperature range of 950 to 700 F. Hot working, If required, may be done in the range of 900 to 500 F.

The cold working characteristics of AL 1060 are excellent. It can readily be cold worked by all conventional methods. Annealing may be done at 650 F followed by air cooling.1060 aluminium alloy metal hardens only from cold working. Tempers H12, H14, H16, H18 are determined by the amount of cold working imparted into the alloy.

1060 aluminum sheet Feature

1060 aluminum sheet Have good elongation and tensile strength, can satisfy completely the requirements of conventional processing (stamping, stretch) high formability.

For industrial pure aluminium, high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but strength is low, heat treatment can not be improved machinability is bad; Gas welding, hydrogen welding and resistance welding, is not easy to brazing; Under various pressure processing and extension, bending.

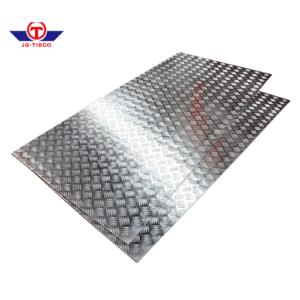

Type:

Hot Rolled, Cold Rolled, Plain Aluminium Sheets, Mirror Finish Sheets, Checkered Plates, Diamond Pattern Plates

Finish:

Mill Finish, Polished, Close Tolerance Polished Sheets and Plates

Application of 1060 aluminum sheet / plate

It is often used in the industrial manufacture of large storage tanks. So, It’s also a commonly used industrial pure aluminum in the aluminum sheet family.

1060 aluminum sheet is also used in products with low requirements for strength. Such as face mask nose wire, billboards, nameplates, building exterior decoration, kitchen sinks, lamp holders, fan leaves, electronic parts, clock and disk surfaces, reflective appliances, etc.

The heat treatment process of 1060 aluminum sheet

- Hot-rolled 1060 aluminum sheet uses: Face mask nose wire, soft battery connection, bus interior, auto parts, aluminum-plastic panel, signage, lamps, wide curtain wall, bus luggage rack / floor / pattern board, etc.

- Hot rolled medium-thickness 1060 aluminum sheet uses: Aluminum bus bar, car radiator, new energy car charging pile, mold, etc.

- Hot-rolled 1060-O aluminum sheet uses: Face mask nose wire, automobile heat shield, electronic tag, soft battery connector, the battery tabs materials.

Product Inventory

Packaging And Shipping

Our Service

JiuGang Tisco Steel offers a wide range of advanced and standard tinplate machining services for tinplate products. We specialize in customized machining services to meet your most challenging tinplate needs.

The tinplate services we can provide include turning, milling, planing, drilling, boring, grinding, gear cutting, and CNC machining services. Of course, we can offer deformation processing services such as bending, cutting, rolling, and stamping.

Why choose us?

JiuGang Tisco Steel has developed a quality control system to ensure that we provide our customers with the highest quality tinplate materials that meet all their specifications. Our Quality Assurance Policy has established guidelines for providing products and services that exceed customer expectations. We are an ISO 9001-2015 certified company. Our management team and all of our employees are committed to constantly improving our service and our quality system.

Contact Us

We offer our customers the opportunity to increase profitability by meeting their just-in-time production schedules and offering customized services to meet end-user-specific requirements. JG.tisco Steel has always been committed to improving customer service and product quality and providing high-value solutions for customers’ businesses. Satisfying the needs of customers is our daily work goal!

Shandong Jiugang Tisco Steel Co., Ltd.

Shandong Jiugang Tisco Steel Co., Ltd.