Common Trade Names: Monel 400, 합금 400; 니켈 400; Nickelvac 400; Nicorros 400.

Monel® Alloy nickel-copper alloy 400 (UNS N04400; W.Nr. 2.4360 그리고 2.4361) is a solid-solution alloy that can be hardened only by cold working. It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments.

합금 400 is widely used in many fields, especially marine and chemical processing. Typical applications are valves and pumps; pump and propeller shafts; marine fixtures and fasteners; electrical and electronic components; springs; chemical processing equipment; gasoline and fresh water tanks; crude petroleum stills, process vessels and piping; boiler feed water heaters and other heat exchangers; and deaerating heaters.

Available Product Forms:

파이프, tube, 시트, strip, plate, round bar, flat bar, forging stock, hexagon, 철사

명세서

MONEL® alloy 400 is designated as UNS N04400 and Werkstoff Nr. 2.4360 그리고 2.4361. It is listed in NACE MR-01-75 for oil and gas service.

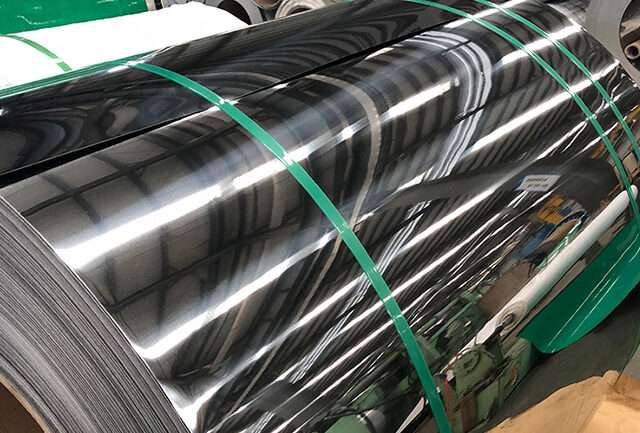

그릇, Sheet, and Strip: – BS3072NA13 (Sheet and Plate), BS3073NA13 (조각), ASTM B 127, ASME SB 127 (그릇,Sheet, and Strip), SAE AMS 4544 (Sheet, 조각, and Plate),

에서 17750 (그릇, Strip and Sheet), QQ-N-281 (그릇, Sheet, 조각, Bar, Rod, Wire, and Forgings)

Bar, Rod, Wire, and Forgings – BS3075NA13 (Wire), BS3076NA13 (Bar), ASTM B 164 (Rod, Bar, and Wire), ASTM B 564 (Forgings), ASME SB 164 (Rod, Bar, and Wire), ASME SB 564 (Forgings), AECMA PrEN 2305 (Wire for Rivets), SAE AMS 4675 (Bars and Forgings),SAE AMS 4730 (Wire), SAE AMS 4731 (Wire and Ribbon), 에서 17752 (Rod and Bar), 에서 17753 (Wire), 에서 17754 (Forgings), VdTÜV 263 (Sheet, 그릇, Bar, and Tubing), QQ-N-281 (그릇, Sheet, 조각, Bar, Rod, Wire, and Forgings)

Pipe and Tube – BS3074NA13 (튜브), ASTM B 163 (Condenser and Heat Exchanger Tube), ASTM B 165 (Seamless Pipe and Tube), ASTM B 725 (Welded Pipe), ASTM B 730 (Welded Tube), ASTM B 751 (Welded Tube), ASTM B 775 (Welded Pipe), ASTM B 829 (Seamless Pipe and Tube), ASME SB 163 (Condenser and Heat Exchanger Tubes), ASME SB 165 (Seamless Pipe and Tube), ASME SB 725 (Welded Pipe), ASME SB 730 (Welded Tube), ASME SB 751 (Seamless and Welded Tube), ASME SB 775 (Seamless and Welded Pipe), ASME SB 829 (Seamless Pipe and Tube), SAE AMS 4574 (Seamless Tubing), 에서 17751 (Pipe and Tube), VdTÜV 263 (Sheet, 그릇, Bar, and Tubing),

Welding Products – MONEL Filler Metal 60-AWS A5.14/ERNiCu-7; MONEL Welding Electrode 190-AWS A5.11/ENiCu-7.

Other Products – ASTM B 366, ASME SB 366 (Welded Fittings), SAE AMS 7233 (Rivets), 에서 17743 (화학적 구성 요소)

Trademark Notice: Some names are trade names and/or trademarks of specific manufacturers. American Special Metals, Corp. is not affiliated with any manufacturer(에스). Orders will be filled to meet specifications from any available source(에스). Names are listed solely for reference to help identify products consistent with listed specifications.

Monel® Alloy 400 is a Registered Trademark of Special Metals Corporation and Its subsidiaries.

American Special Metals, Corp. makes all reasonable efforts to ensure the accuracy and correctness of the data in this document but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

화학적 구성 요소

Limiting Chemical Composition, % by Weight

니켈 (plus Cobalt)……………………………………………..63.0 분.

탄소………………………………………………………………..0.3최대.

망간………………………………………………………….2.0 최대.

철……………………………………………………………………..2.5최대.

황………………………………………………………………0.024최대.

규소…………………………………………………………………0.5최대.

구리…………………………………………………………….28.0 -34.0

산동 Jiugang Tisco Steel Co., (주).

산동 Jiugang Tisco Steel Co., (주).